ເລື້ອຍໆອົງປະກອບສາມາດຖືກອອກແບບໃຫມ່ເພື່ອຕັດຈາກຫນຶ່ງຊິ້ນ, ແທນທີ່ຈະຫຼາຍຊິ້ນ. ແທນທີ່ຈະຕັດກອບຈາກສີ່ພາກສ່ວນແຍກຕ່າງຫາກຢູ່ໃນແຕ່ລະແຈ, ມັນສາມາດຕັດອອກຈາກທໍ່ດຽວທີ່ບໍ່ໄດ້ຖືກຕັດແລ້ວງໍເພື່ອກອບເປັນ.

ນີ້ສາມາດຫຼຸດຜ່ອນພາກສ່ວນທີ່ຕ້ອງການໃນ BoM ແລະຜະລິດຕະພັນທີ່ຖືກຕ້ອງແລະເຂັ້ມແຂງຂຶ້ນໂດຍການນໍາໃຊ້ນີ້, ການເຮັດເລື້ມຄືນແລະຄວາມຖືກຕ້ອງຂອງຜະລິດຕະພັນສາມາດໄດ້ຮັບການປັບປຸງ.

ຂໍ້ດີຂອງເຄື່ອງຕັດທໍ່ໂລຫະ ແລະເສັ້ນໃຍເລເຊີແຜ່ນ:

1. ຕັດສາຍແລະຮູທີ່ມີເສັ້ນຜ່າກາງທີ່ແຕກຕ່າງກັນຈາກທິດທາງທີ່ແຕກຕ່າງກັນກ່ຽວກັບທໍ່

2. ຕັດພາກສ່ວນ inclined ໃນຕອນທ້າຍຂອງທໍ່

3. ຕັດທໍ່ສາຂາ intersected ກັບທໍ່ວົງຕົ້ນຕໍ

4. ຕັດຂຸມສີ່ຫຼ່ຽມມົນ, ຮູທີ່ມີຮູບຊົງແອວແລະຂຸມວົງຢູ່ໃນທໍ່

5. ຕັດທໍ່

6. ຕັດທຸກປະເພດຂອງກາຟິກໃນດ້ານຂອງທໍ່ຮຽບຮ້ອຍ

7. ແຜ່ນອາຫານຂະໜາດທີ່ຕ່າງກັນ

8. ຕັດຮູໃສ່ກ່ອງ molding

ອອກແບບ

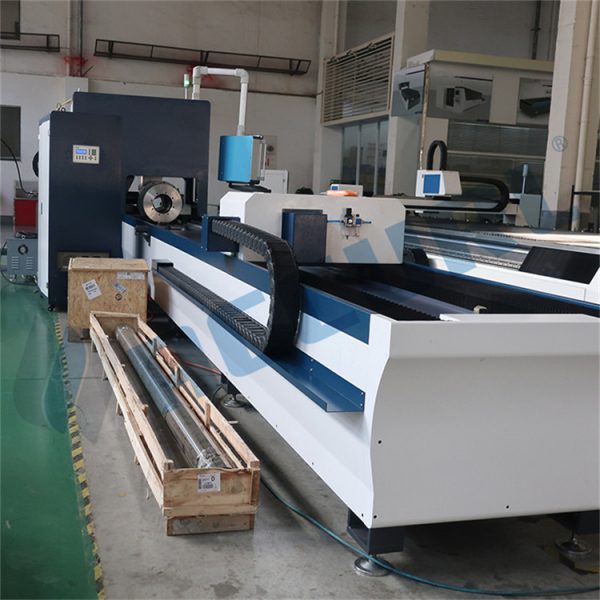

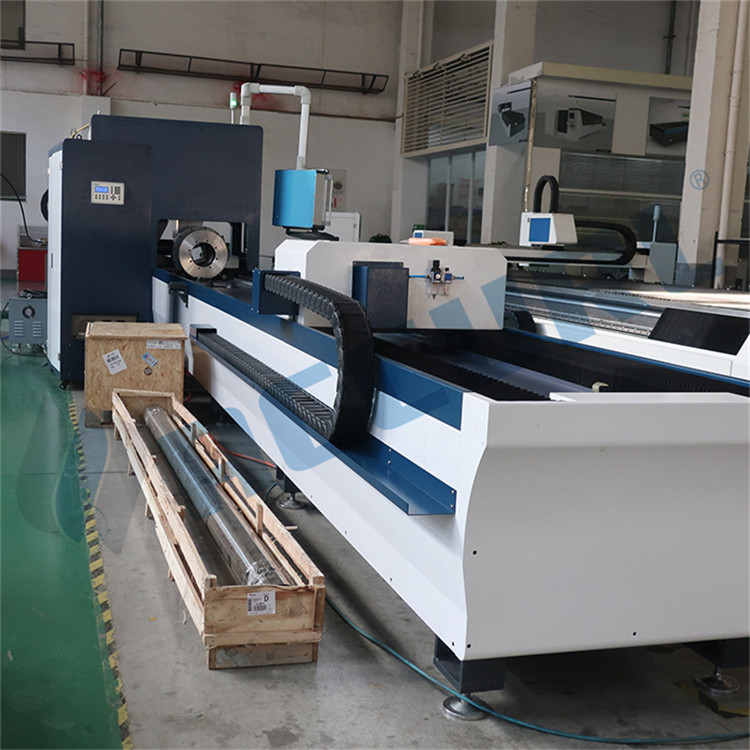

ການອອກແບບມາດຕະຖານເອີຣົບ, ທຸກໆລາຍລະອຽດແມ່ນຄວາມພະຍາຍາມເພື່ອຄວາມສົມບູນແບບ, ຕາຕະລາງການດໍາເນີນງານ, ການອອກແບບໂຄມໄຟ suspension, ແຂບສະແຕນເລດ, ພວກເຮົາຈະສ້າງຜະລິດຕະພັນອຸດສາຫະກໍາທີ່ມີຄວາມຕ້ອງການຂອງຜະລິດຕະພັນຫລູຫລາ.

ຫົວຕັດເລເຊີ

ໂຄງສ້າງພາຍໃນຂອງຫົວເລເຊີຖືກປະທັບຕາຢ່າງສົມບູນເພື່ອຫຼີກເວັ້ນການປົນເປື້ອນຂອງສ່ວນ optical. ຫົວເລເຊີຮັບຮອງເອົາການປັບຈຸດສູນກາງສອງຈຸດແລະໂຄງສ້າງ cam ແມ່ນໃຊ້ສໍາລັບການສຸມໃສ່. ການປັບແມ່ນຖືກຕ້ອງແລະສະດວກ, ການອອກແບບ modular, ຄວາມແມ່ນຍໍາສູງແລະການບໍາລຸງຮັກສາງ່າຍ.

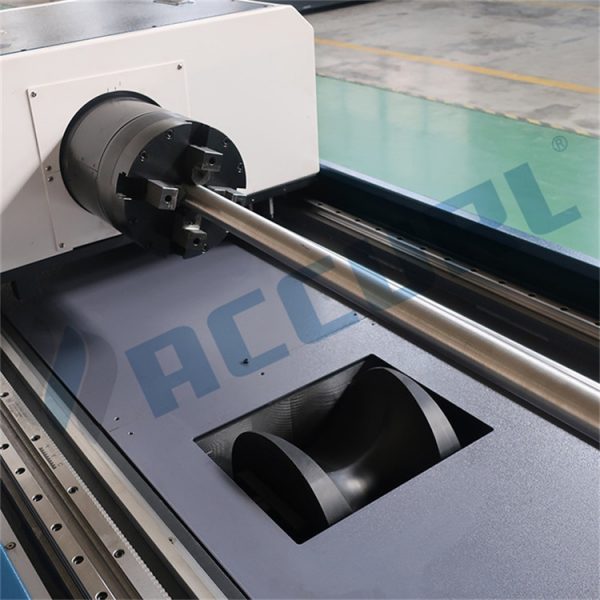

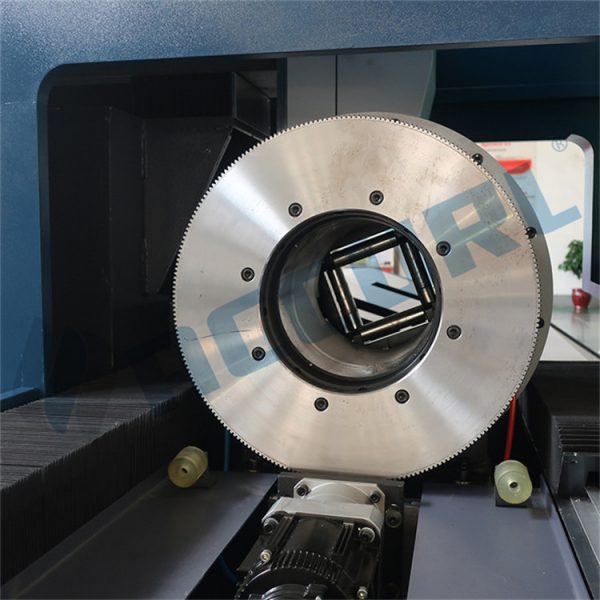

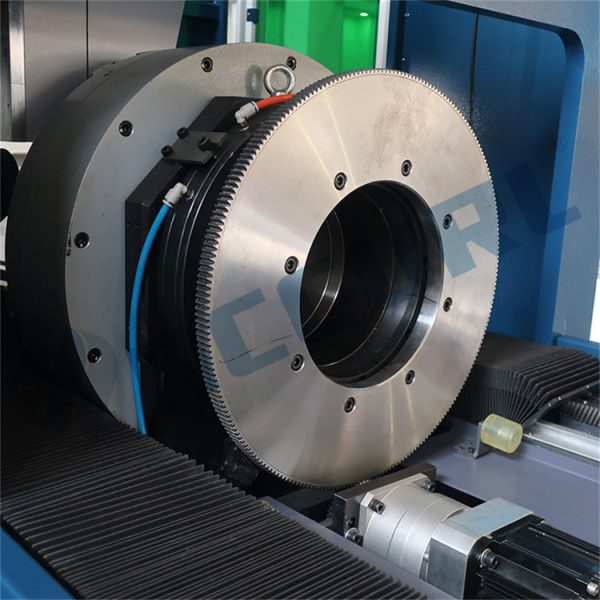

ດິຈິຕອລ full stroke chuck

chuck stroke ເຕັມໂດຍບໍ່ມີການປັບຄູ່ມື. ລະບົບຕິຊົມຄວາມກົດດັນອັດສະລິຍະ, ການປັບຄວາມກົດດັນອັດຕະໂນມັດຕາມເສັ້ນຜ່າສູນກາງແລະຄວາມຫນາຂອງທໍ່ທີ່ແຕກຕ່າງກັນ. ການກໍານົດອັດສະລິຍະແລະການຍຶດທໍ່ທໍ່ຕ່າງໆ, ການຕິດຕາມເວລາທີ່ແທ້ຈິງແລະການແຈ້ງເຕືອນ, ປອດໄພແລະມີປະສິດທິພາບ.

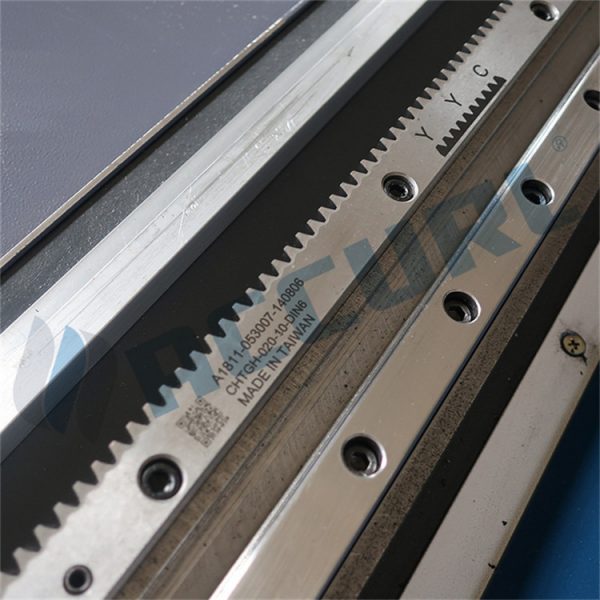

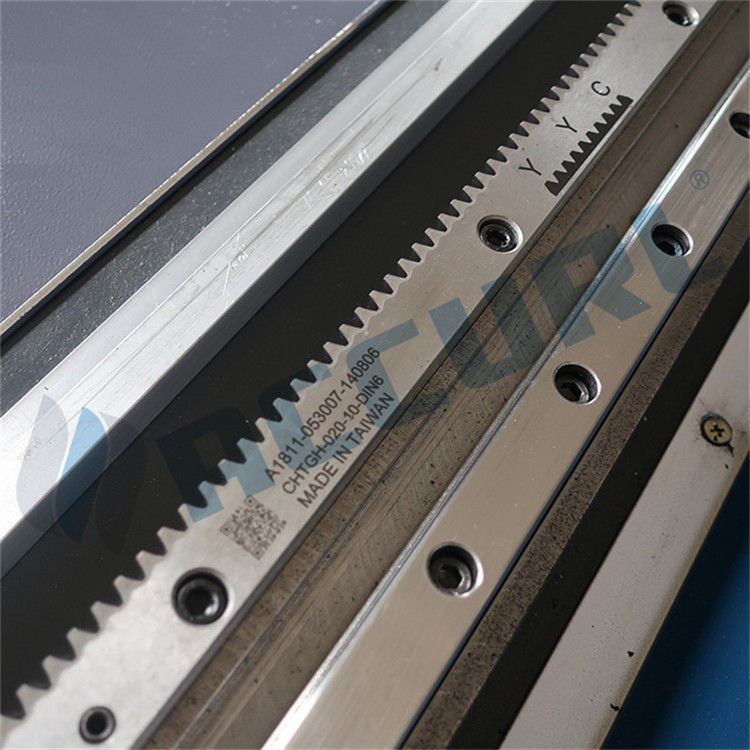

1. ໂຄງສ້າງກົນຈັກປະສົມປະສານຕຽງເຄື່ອງ, ບັນລຸການປະຕິບັດທີ່ຫມັ້ນຄົງ. Rack ແລະຄູ່ມື rails ຮັບຮອງເອົາການປົກປ້ອງຢ່າງເຕັມສ່ວນເພື່ອຫຼີກເວັ້ນການປົນເປື້ອນຝຸ່ນ, ດັ່ງນັ້ນເພື່ອເສີມຂະຫຍາຍອາຍຸການຂອງພາກສ່ວນລະບົບສາຍສົ່ງແລະຮັບປະກັນການແລ່ນຄວາມຖືກຕ້ອງຂອງຕຽງເຄື່ອງ;

2.This model adopts AC servo motors ຂັບລົດລະບົບ, ພາກສ່ວນລະບົບສາຍສົ່ງ adopts racks, pinions ແລະເສັ້ນຄູ່ມື rails, ຮັບປະກັນຄວາມໄວສູງ, ຄວາມແມ່ນຍໍາສູງແລະຄວາມຫນ້າເຊື່ອຖືສູງຂອງອຸປະກອນ;

3. ເຕັມອັດຕະໂນມັດ chuck pneumatic ສາມາດບັນລຸໄດ້ໄວດ້ວຍຕົນເອງຈຸດສູນກາງແລະວັດຖຸ clamping, ແລະຄວາມກົດດັນອາຍແກັສສາມາດໄດ້ຮັບການປັບໃນເວລາດຽວກັນ, ເພື່ອເຮັດໃຫ້ແນ່ໃຈວ່າມີຄວາມເຂັ້ມແຂງ clamping ຫມັ້ນຄົງແລະເຊື່ອຖືໄດ້;

3. ເຕັມອັດຕະໂນມັດ chuck pneumatic ສາມາດບັນລຸໄດ້ໄວດ້ວຍຕົນເອງຈຸດສູນກາງແລະວັດຖຸ clamping, ແລະຄວາມກົດດັນອາຍແກັສສາມາດໄດ້ຮັບການປັບໃນເວລາດຽວກັນ, ເພື່ອເຮັດໃຫ້ແນ່ໃຈວ່າມີຄວາມເຂັ້ມແຂງ clamping ຫມັ້ນຄົງແລະເຊື່ອຖືໄດ້;

4. ຮັບຮອງເອົາວິທີການໃຫ້ອາຫານທີສອງໂດຍສະເພາະສໍາລັບການປຸງແຕ່ງທໍ່ຂະຫນາດນ້ອຍ, ແກ້ໄຂບັນຫາຄວາມແມ່ນຍໍາຂອງການຕັດທໍ່ຂະຫນາດນ້ອຍທີ່ມີຄວາມຍາວ 6 ແມັດຈາກເຄື່ອງຈັກພື້ນເມືອງ.

4. ຮັບຮອງເອົາວິທີການໃຫ້ອາຫານທີສອງໂດຍສະເພາະສໍາລັບການປຸງແຕ່ງທໍ່ຂະຫນາດນ້ອຍ, ແກ້ໄຂບັນຫາຄວາມແມ່ນຍໍາຂອງການຕັດທໍ່ຂະຫນາດນ້ອຍທີ່ມີຄວາມຍາວ 6 ແມັດຈາກເຄື່ອງຈັກພື້ນເມືອງ.

| ຂໍ້ມູນສະເພາະດ້ານເຕັກນິກການຕັດທໍ່ | |

| ເສັ້ນຜ່າສູນກາງສູງສຸດ (ມມ) | Ø210 |

| ຂະໜາດທໍ່ສີ່ຫຼ່ຽມສູງສຸດ(ມມ) | 140×140 |

| ຂະໜາດທໍ່ສີ່ຫຼ່ຽມສູງສຸດ(ມມ) | 170×120 |

| ເສັ້ນຜ່າສູນກາງຕໍ່າສຸດ(ມມ) | Ø20(Ø12ທາງເລືອກ) |

| ຄວາມຍາວທໍ່ສູງສຸດ (ມມ) | 6500 |

| ຄວາມຍາວທໍ່ນ້ອຍ (ສຳລັບການໂຫຼດອັດຕະໂນມັດ) | 3000 |

| ສູງສຸດ. ນ້ຳໜັກທໍ່ (kg/m) | 37.5 |

| ຄວາມໜາສູງສຸດຂອງວັດສະດຸ(mm)(for1kwTo4kw) | 0.5-12 |

| ຄວາມໜາຕ່ຳສຸດຂອງວັດສະດຸ(ມມ) | 0.8 |

| ການໂຫຼດອັດຕະໂນມັດ | ທາງເລືອກ |

| ການໂຫຼດອັດຕະໂນມັດ | ທາງເລືອກ |

| ຕັດຫົວ | 2D |

| ຈໍານວນ Chuck | 1 |

| Chuck ກາງ | ແມ່ນແລ້ວ |

| ຄວາມຍາວທໍ່ສຸດທ້າຍ(ມມ) | 185 |

| ຄວາມໄວຂອງ Driver Chuck(m/dk.) | 90 |

| ການເລັ່ງຂອງ Driver Chuck(m/s²) | 10 |

| ຄວາມຖືກຕ້ອງ(ມມ) | ±0,20 |

| ຄວາມຖືກຕ້ອງຂອງການຈັດຕຳແໜ່ງ(ມມ) | ±0,05 |

| ປະເພດທໍ່ | ທໍ່,ສີ່ຫຼ່ຽມ,ສີ່ຫຼ່ຽມ, Eliptic H,C,U,L |

ທໍ່ແລະໂປໄຟແມ່ນຖືກ ນຳ ໃຊ້ໃນຫລາຍໆດ້ານ, ຈາກວິສະວະ ກຳ ກົນຈັກແລະການກໍ່ສ້າງລະບົບຈົນເຖິງອຸດສາຫະ ກຳ ເຟີນີເຈີ. Lasers ໄດ້ເປີດໃຫ້ມີຄວາມເປັນໄປໄດ້ໃນການອອກແບບ ໃໝ່, ສະນັ້ນນັກອອກແບບນັບມື້ນັບຫຼາຍໄດ້ຮັບຜົນປະໂຫຍດຈາກທໍ່ຕັດດ້ວຍເລເຊີແລະໂປໄຟເພື່ອໃຫ້ຄວາມຕ້ອງການເພີ່ມຂື້ນຢ່າງຫຼວງຫຼາຍ. ACCURL ສະ ເໜີ ຊຸດເຄື່ອງຕັດທໍ່ເລເຊີທີ່ ນຳ ສະ ເໜີ ຄວາມຍືດຫຍຸ່ນຂອງທໍ່ 3D ຂະ ໜາດ ໃຫຍ່ເພື່ອຕັດຫລາກຫລາຍຮູບຊົງລວມທັງຮອບ, ສີ່ຫລ່ຽມ, I-beam ແລະໂປແກມໂຄງສ້າງອື່ນໆ. ມັນຖືກອອກແບບເພື່ອເພີ່ມສະມັດຕະພາບການຜະລິດ, ງ່າຍດາຍແລະເຂັ້ມແຂງການປະກອບຂອງສ່ວນປະກອບແລະປັບປຸງຄວາມທົນທານຂອງສ່ວນປະກອບຜ່ານການຕັດເລເຊີທີ່ຊັດເຈນກວ່າ. ຄົ້ນພົບວິທີແກ້ໄຂທີ່ສົມບູນແບບ ສຳ ລັບການຕັດທໍ່ເລເຊີແລະຮຽນຮູ້ສິ່ງທີ່ ACCURL ເຄື່ອງຕັດທໍ່ເລເຊີສາມາດເຮັດໄດ້!

ACCURL's ແນະ ນຳ ການຜະລິດທໍ່ ໃໝ່ ແລະເຕັກໂນໂລຢີການປະມວນຜົນໂປຣແກຣມ - ລະບົບຕັດທໍ່ເລເຊີໄຟເບີ. ມີປະສົບການຫລາຍກວ່າ 30 ປີໃນການອອກແບບແລະການຜະລິດປະສົບການໃນເຕັກໂນໂລຢີການຕັດທໍ່, ACCURL ມີຄວາມຊ່ຽວຊານດ້ານວິທີແກ້ໄຂ ສຳ ລັບອຸດສະຫະ ກຳ ທໍ່ແລະທໍ່, ແລະເສັ້ນຕັດເລເຊີ ໃໝ່ ແມ່ນວິທີການແກ້ໄຂທີ່ສຸດ ສຳ ລັບການເຂົ້າຮ່ວມຂະບວນການເຄື່ອງຈັກຫຼາຍຢ່າງໃນລະບົບດຽວເພື່ອຄວາມຍືດຫຍຸ່ນສູງສຸດ , ອັດຕະໂນມັດແລະການປະຕິບັດ.