ຄຸນລັກສະນະຂອງພວກເຮົາ 1000watt laser machine

1.Stability and reliability of light path system and control system

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours

3.Higher cutting quality and efficiency ,cutting speed is up to 80m/min with appearance and beautiful cutting edge

4.German high performance reducer,gear and rack;Japanese guide and ball screw.

Applicable Industry and materials of ເຄື່ອງຕັດເລເຊີໃຍ

ເຄື່ອງຕັດເລເຊີໃຍ application:

metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agriculture and forestry machinery, elevator manufacture, special vehicles, household appliances, tools, processing, IT manufacturing, oil machinery, food machinery, diamond tools, welding, welding gear, metal materials, decoration advertising, laser surface treatment of foreign processing services, such as all kinds of machinery processing industry.

ຂອງພວກເຮົາ ເຄື່ອງຕັດເລເຊີໃຍ's Application Materials:

Professional used to cut thin sheet metal, in a variety of high quality 0.5 -3 mm carbon steel sheet cutting, can also be cutting stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminium zinc plate and other metal.

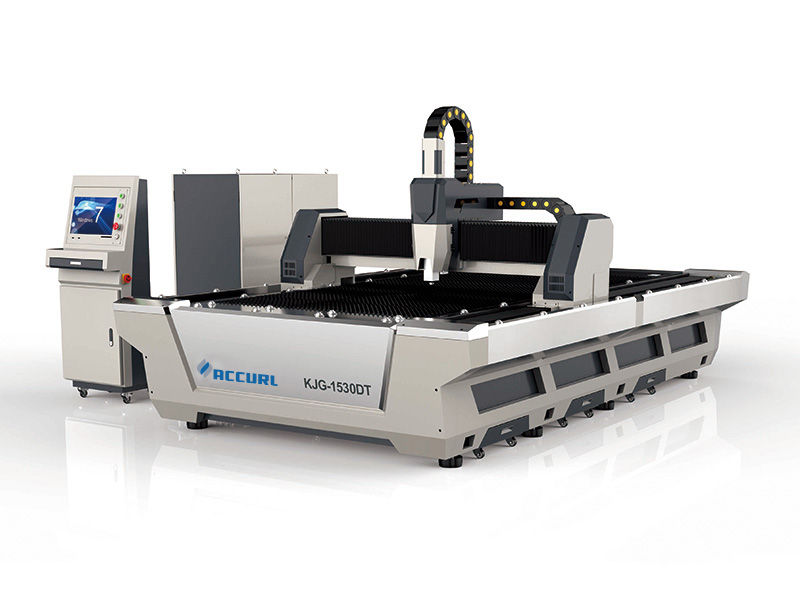

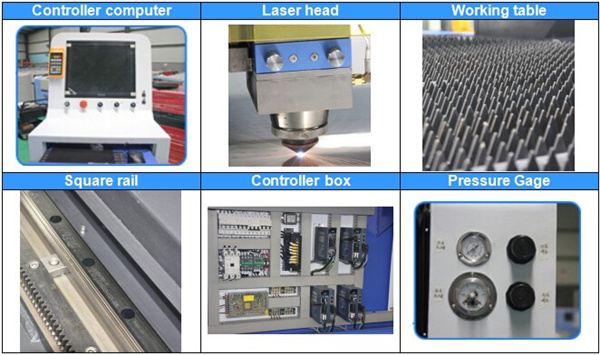

Main machine pictures of 1kw laser cutting machine

ລາຍລະອຽດດ່ວນ

ຄໍາຮ້ອງສະຫມັກ: ການຕັດເລເຊີ

ເງື່ອນໄຂ: ໃໝ່

ປະເພດເລເຊີ: ເລເຊີໄຟເບີ

ເອກະສານທີ່ໃຊ້ໄດ້: ໂລຫະ

ຄວາມຫນາຕັດ: 0-20mm

ພື້ນທີ່ຕັດ: 1300 * 2500mm

ຄວາມໄວຕັດ: 25m / ນາທີ

CNC ຫຼືບໍ່: ແມ່ນແລ້ວ

ຮູບແບບການເຮັດຄວາມເຢັນ: ຄວາມເຢັນຂອງນໍ້າ

Control Software: bechoff ( Cypcut )

ຮູບແບບກາຟິກສະ ໜັບ ສະ ໜູນ: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

ການຢັ້ງຢືນ: CE, ISO, SGS

ມີການບໍລິການຫລັງການຂາຍ: ວິສະວະກອນທີ່ມີໃຫ້ບໍລິການເຄື່ອງຈັກຢູ່ຕ່າງປະເທດ

Model: 1000 watt laser

ວັດສະດຸຕັດ: ເຫຼັກເສັ້ນເຫຼັກກາກບອນສະແຕນເລດ (ເຄື່ອງຕັດໂລຫະໂລຫະ)

Fiber laser Generator type: Famous brand Raycus ( Made in China )

Fiber Laser cutting head: Lasermech ( From U.S. )

Motors & Drivers: 1500W Fuji servo motor made in Japan

Min. Line Width: ±0.02mm

Working life of fiber module: More than 100000 hours

Warranty time: Whole machine for 3 years (fib

Parameter of our ເຄື່ອງຕັດເສັ້ນໃຍແກ້ວ

| Machine Model | ຂະ ໜາດ 2500 * 1300mm |

| ພະລັງງານເລເຊີ | 300W/500W/1000W/3000W |

| Fiber laser Generator type | Famous brand Raycus ( Made in China ) |

| ຄວາມຍາວຄື້ນເລເຊີ | 1064nm |

ຄຸນະພາບຂອງເລເຊີ | <0.373mrad |

| ຕາຕະລາງເຮັດວຽກ | Sawtooth |

| ຫົວຕັດ Fiber Laser | Lasermech ( From U.S. ) |

| ເລນໂຟກັສ | Lasermech made in USA |

| ຊີວິດການເຮັດວຽກຂອງໂມດູນເສັ້ນໄຍ | ຫຼາຍກວ່າ 100000 ຊົ່ວໂມງ |

| ມໍເຕີ ແລະຄົນຂັບລົດ | 1500W Fuji servo motor made in Japan |

| ເຄື່ອງຫຼຸດຜ່ອນ | 3 sets from Germany |

| ລາງລົດໄຟຄູ່ມື | High accuracy PMI brand from Taiwan |

| ລະບົບສາຍສົ່ງ | Dual Rack & Pinion type |

| Rack system | Germany rack |

| ລະບົບຕ່ອງໂສ້ | Igus made in Germany |

| ເຄື່ອງເຢັນນໍ້າ | TEYU( S&A) brand, CW6000 |

| ລະບົບຄວບຄຸມ | ລະບົບການຄວບຄຸມເລເຊີແບບມືອາຊີບ--Cypcut

|

| ປະເພດຕໍາແໜ່ງ | Red Dot |

| ຄວາມຫນາຕັດ | ≤3mm(stainless steel) ≤6mm(carbon steel) |

| ສູງສຸດ. ຄວາມໄວໃນການແລ່ນບໍ່ເຮັດວຽກ | 1400mm/s |

| ຄວາມໄວຕັດ | 300mm/s |

| ຄວາມຖືກຕ້ອງຂອງ ຕຳ ແໜ່ງ | ± 0.05mm / ມ |

| ຄວາມໄວຂອງ ຕຳ ແໜ່ງ | 20m / ນາທີ |

| ຕ່ຳສຸດ ຄວາມກວ້າງເສັ້ນ | ± 0.02mm |

| ການນໍາໃຊ້ພະລັງງານ | ≤12KW |

| Carry weight | 700KG |

| ແຮງດັນ | 380V/50HZ,3PH |

| ອາຍແກັສເສີມສໍາລັບການຕັດ | ອົກຊີເຈນ, ໄນໂຕຣເຈນ, ອາກາດ |

| ຊອບແວທີ່ເຂົ້າກັນໄດ້ | Autocad, Coreldraw, ແລະອື່ນໆ |

| ຮູບແບບກາຟິກ | Nc |

| ວິທີການເຮັດວຽກ | PC control |

| ການຈັດອັນດັບການປົກປ້ອງພະລັງງານທັງຫມົດ | IP54 |

| Machine weight | About 4000KG |

| ຂະໜາດເຄື່ອງ | 4800*2600*1800mm |

| ເວລາຮັບປະກັນ | Whole machine for 3 years (fiber module 2 years ) |

Quality control of 1000watt laser

Quality is our sincerest respect offered to all our customers, and it is the most important factor to maintain long-term business relationships with us.

We always pay more attention to the quality of laser cutting machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser power meter.

In the mechanical assemble process, the laser interferometer, laser collimator, dial indicator and marble plate are used; In the laser assemble process, the laser power meter and optical microscope are adopted.